Products & Services

PROGRAM MANAGEMENT

Based on the priorities of your program, JRI will manage product work flow per your schedule requirements and keep you informed as required through completion.

JRI maintains a program management team for each of our customers. We strive to assign a team for you that understands your way of business.

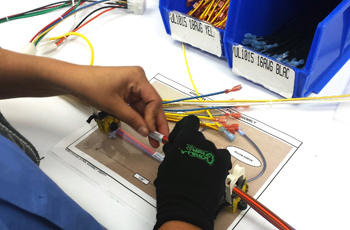

HIGH RELIABILITY ASSEMBLY

JRI reliability is unsurpassed in the industry.

Our design and engineering personnel have developed and produced cable and wire harness assemblies for high altitude aircraft as well for durability far below the ocean’s surface. Planning and production techniques for weaponry are also applied to commercial and industrial systems.

JRI’s proprietary cable lay process and equipment allow small orders to be manufactured quickly and efficiently. Our versatility enables us to produce and deliver any unit with wires and connecting hardware of any size within days if needed. Our quality control systems coordinate material needs, production planning process, inspection and test to meet the following standards:

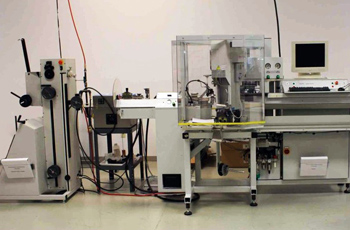

LASER MARKING SYSTEM

Full graphics capabilities including upper and lower cases of alpha-numeric characters in any language, bar codes, logos etc.

Full graphics capabilities including upper and lower cases of alpha-numeric characters in any language, bar codes, logos etc.

The M-100L is a fully automatic, computer controlled, high speed, solid state UV Laser wire and cable marking system.

Lasers have become one of the preferred means of marking wire and cable because of their reliability, throughput, cleanliness and very low maintenance requirements.

A key aspect of UV Laser marking is the absorption of the laser radiation on the surface of the wire insulation that changes its color without any damage to the material.

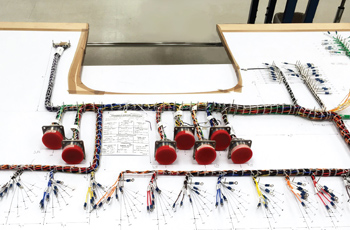

TOOLING CAPABILITY

JRI’s form board process begins with design models in order to result in product consistency and control to conform with AS9100 standards.

Special tooling requirements are always met when needed, no matter how complex or simple the routing and harness design. At JRI, our policy of investing in our customer-partners creates a culture of success for all.

MOLDING

High temperature molded elastomers and polymers are produced to precise specifications for virtually all military, aerospace, aircraft, commercial, bio-medical, and consumer products.

We design mold tooling to best accommodate our customer’s requirements, including multi-leg breakouts in different shapes. Special materials are selected for harsh environments or heavy duty treatment. We can design a custom tool for any angle or degrees to suit your needs.

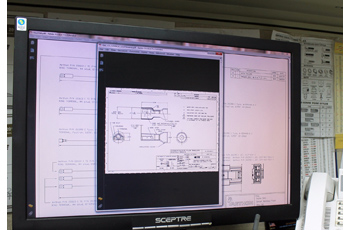

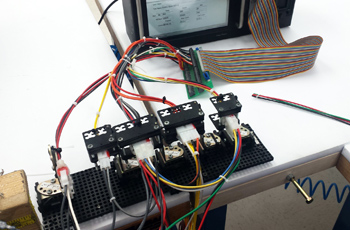

AUTOMATIC TESTING

JRI’s Quality Assurance department is meticulous in analyzing and evaluating each test set for specified tensions, size, capacity, and materials. The switching architecture delivers a powerful combination of high output current and measurement accuracy. A HiPOT algorithm with virtually unlimited expansion capability delivers extremely fast test-cycle time.

Single-scan bi-directional testing detects the location and cause of all low-voltage faults.

Functional testing flexibility enables JRI users to evaluate continuity, isolation and breakdowns in complex, multi-component wiring systems, including: black-boxes, capacitors, diodes, lamps, inductors, relays, resistors, shielded cable termination, solenoids, switches and transistors.

CUSTOMER STOCK ROOMS & DISTRIBUTION

In addition to a maintaining a standing inventory of thousands of components and parts, JRI manages customer stock rooms with required minimums for immediate production and delivery on a global basis.

VENDOR MANAGED INVENTORY

JRI’s vendor-managed inventory data system can be customized to fit your scheduled replenishment or cycle time for on-demand needs. JRI’s Electronic Data Interface carries periodic information updates to meet customer needs.

- Component usage data history

- Continuously updated information

- On-hand parts and materials

- Build to order capability if needed

- Global range

- On-time replenishment

- In the right hands at the right speed at the right time.

REQUEST A QUOTE

We welcome the opportunity to deliver excellence: Complete, to specifications, on time, and co-managed from start to finish. Our goal is to build a long term relationship through reliability, quality and the ability to anticipate your needs in today’s evolving military defense, bio-medical and commercial sectors.